Home

Troubleshooting ideas for common points with industrial lubricants

Industrial lubricants are specialized oils, greases as well as other fluids that can be used to shield machines from wear and tear. These lubricants help to decrease friction among moving components and keep the machinery clean and free of dust. To choose the best industrial lubricant to meet your requirements, you’ll be required to think about the type of machinery you are working with, the type of environment where it is utilized, and the particular specifications of the application.

It is also important to take into consideration the operating environment of your equipment. If your machine is operating under extreme conditions, you’ll need to select an oil that is designed to endure those conditions. Another aspect to consider is the degree that wear and tear that the machinery endures. If your equipment is subject to wear and tear, you will have to select a grease that is able to withstand that type of use.

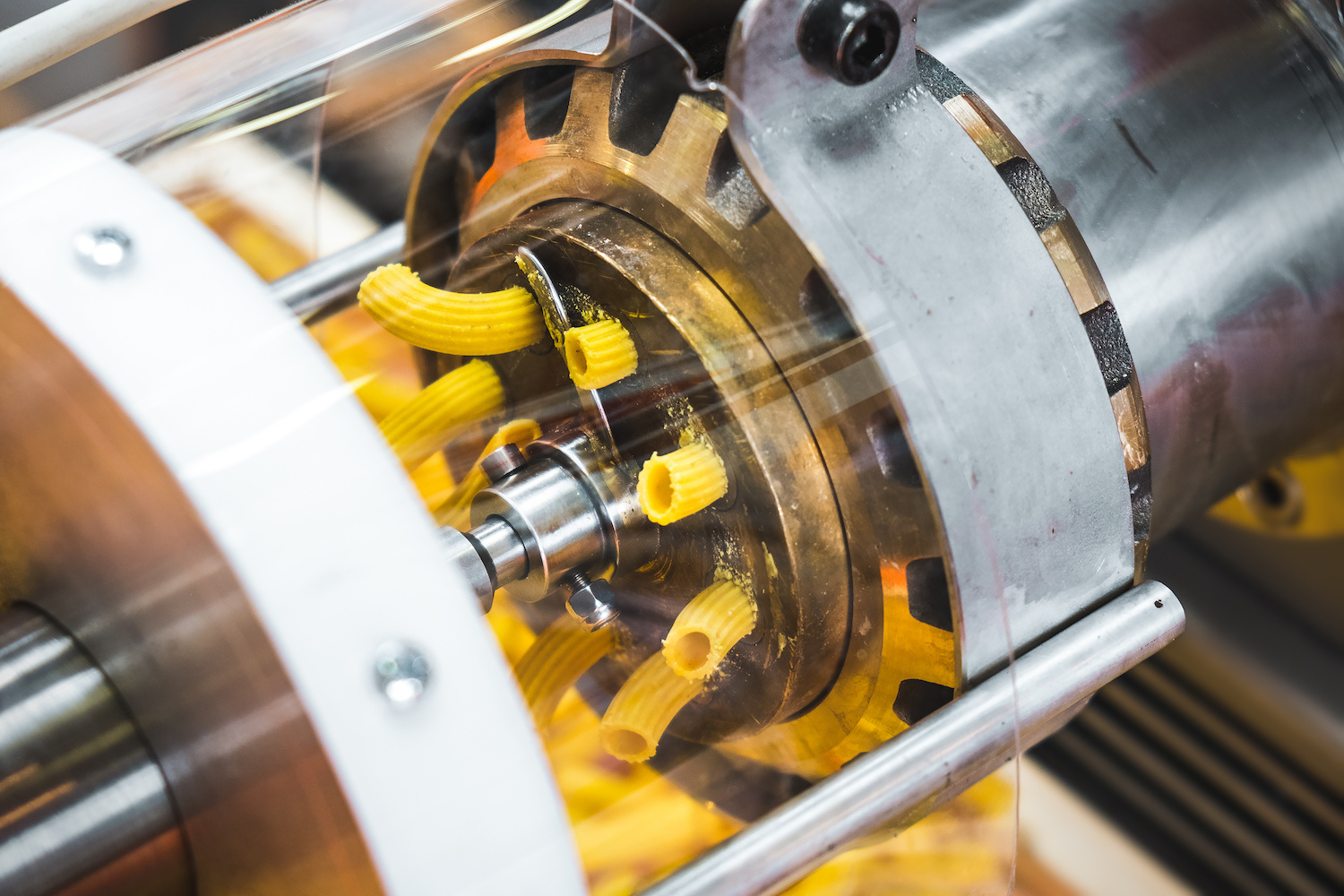

Gear oils are created to shield gears from wear and tear. Additionally, they can also help reduce the sound and vibration. Compressor oils are utilized in air compressors, as well as any other machinery that uses compressed air. When selecting an industrial lubricant It is vital to take into account the temperature at which the equipment and the environment under which it is employed. Certain lubricants are specifically designed for applications in certain environments, such as high-temperature or cold-temperature applications.

Other lubrificanti industriali are designed to be used in general-purpose applications. It is also important to consider how compatible the lubricant the materials that it will come into contact with. Certain lubricants can cause harm to certain kinds of metals or plastics, so it is important to select a lubricant which will work with materials you are using. Some fluids aren’t compatible with certain types of fluids. It is vital to verify the compatibility between the fluid and the lubricant prior use. To generate new information kindly head to Ronchiils

If you believe the lubricant you use may be contaminated, it’s important to act quickly. You can flush the lubricant using a clear solvent. If this doesn’t resolve the issue, you might require replacing the entire batch of fluid. Another issue that is common to arise with industrial lubricants is foam formation. It happens when air bubbles are trapped in the lubricantand cause it to lose its effectiveness and can cause problems with equipment.

They must know how to safely keep, handle and apply lubricants as well as ways to get rid of used fluids. Industrial lubricants can be hazardous, which is why it is important to review your safety protocols on a regular basis. Make sure all employees are aware of the risks that are involved and how to operate safely with lubricants. If you are working in the industrial sector with lubricants, it is essential to follow the manufacturer’s guidelines. This includes the proper storage, handling, and application methods. In the absence of this, it could invalidate your warranty, or cause damage to the equipment.